- Products

- Solutions

- Service

- Company

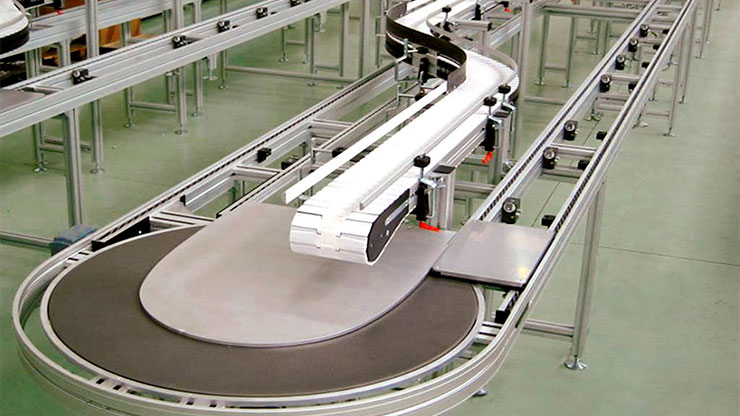

Pallet transport systems are used whenever (manual or automatic) machining, marking or testing of workpieces takes place at defined stations. They also combine conveyor technology and workplace and are used to set up assembly and machining lines for assemblies. Which system is the optimum solution for the respective use depends on different factors such as the weight of the goods to be transported, the space available, etc.

Do you have any questions or would you like to learn more about our pallet transport system? Then please feel free to contact us!

The flexible solution for heavy workpieces

The further development of the RMS for particularly heavy workpieces

Modular structure for a large number of system concepts

For a wide range of system concepts – with high load capacity

Conveying in the smallest space

The economic solution for lightweight goods to be transported

Below you will find a comparison between the RMS, TSG and FMS systems. Further comparisons between RMS and RMS Max as well as FMS and FMS Max can be found on the detailed pages for the respective systems. Our customer advisors will be happy to answer any questions you may have!

| RMS | TSG | FMS | |

| AREAS OF USE | Heavy and large components such as engines, transmissions, axles, washing machines, heaters, etc. | Small and medium-sized components, for example, mobile phones, electric motors, etc. | Small, medium and large components, for example, shock absorbers, instrument panels, seats, headlamps, etc. |

| LOADS | up to 350 kg/WP | up to 300 kg/section | 150 kg/m |

| GUIDE WIDTHS | Standard 400, 500, 600 mm | 200 mm | 160 mm to 1000 mm |

| WORKPIECE CARRIER LENGTH | 400 mm to 2000 mm | 200 mm | 160 mm to 2000 mm |

| SPEEDS | up to 15 m/min | between 5,5 – 21 m/min | up to 18 m/min |

| ACCUMULATION MODE | Accumulating rollers with internal friction | Toothed belt 25 T5 | Accumulating roller chain or belt |

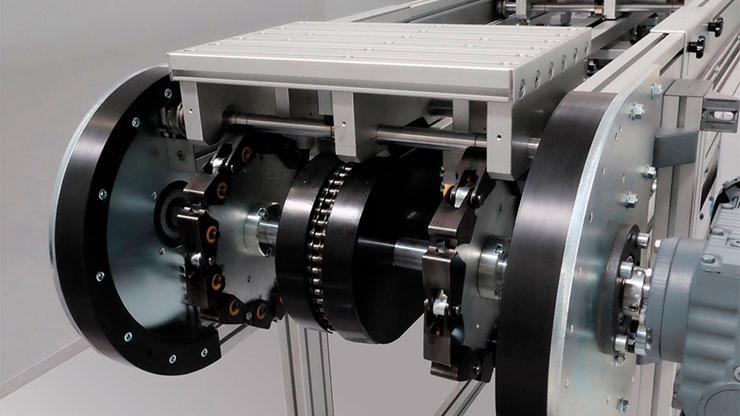

| DRIVE | E-motor, tangential chain / accumulating roller | E-motor, toothed belt drive | E-motor, pulley, chain wheel (sprocket) |