- Products

- Solutions

- Service

- Company

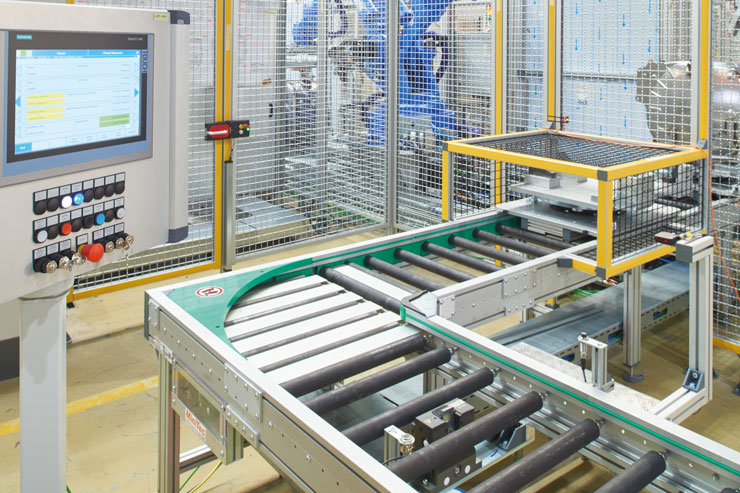

RMS is a workpiece carrier transfer system based on heavy-duty accumulator rollers, which ensure free circulation for assembly, testing and machining tasks. It is possible to accumulate and buffer the workpiece carriers, manual workplaces can also be easily integrated into the conveying section. The carrier pallets have a standard width of 400 or 500 millimetres and are designed for a maximum load of 500 kilograms. The system ensures smooth material flow and is typically used in production lines, assembly technology and factory automation. The RMS roller conveyor system is used, among other things, in the production of vehicle components such as car seats or drive trains, the production of large household appliances as well as the conveyor infrastructure of a warehouse logistics system.

A further development of the RMS is the RMS Max, which is suitable for particularly heavy workpieces.

Below you will find a comparison between the RMS and RMS Max systems. Our customer advisors will be happy to answer any further questions you may have!

| RMS | RMS Max | |

| FIELDS OF APPLICATION | Heavy and large components e.g. engines, gearboxes, axles, silencers, heat pumps etc. | Particularly heavy and large components e.g. truck engines, gearboxes, rear axles, battery packs etc. |

| LOADS | up to 350 kg/WT | up to 1.000 kg/m |

| GUIDING WIDTHS | Standard 400, 500, 600 mm | ≥ 600mm, freely selectable with split rollers |

| LENGTH OF WORKPIECE CARRIERS | 400 mm to 2000 mm | 600 mm to 2.500 mm |

| STANDARD ROLLER DIVISION | 60, 120, 180 mm | 75, 150mm |

| ROLLER DIAMETER | 50 mm | 60 mm |

| LENGTH PER DRIVE | up to 9 m | up to 9 m |

| LOAD PER DRIVE | up to 1.200 kg | up to 6.000 kg |

| SPEEDS | up to 15 m/min | up to 9 m/min |

| ACCUMULATION OPERATION | Accumulation rollers with internal friction | Accumulation rollers with internal friction |

| DRIVE | E-motor, tangential chain/accumulation roller | E-motor, tangential chain/accumulation roller |