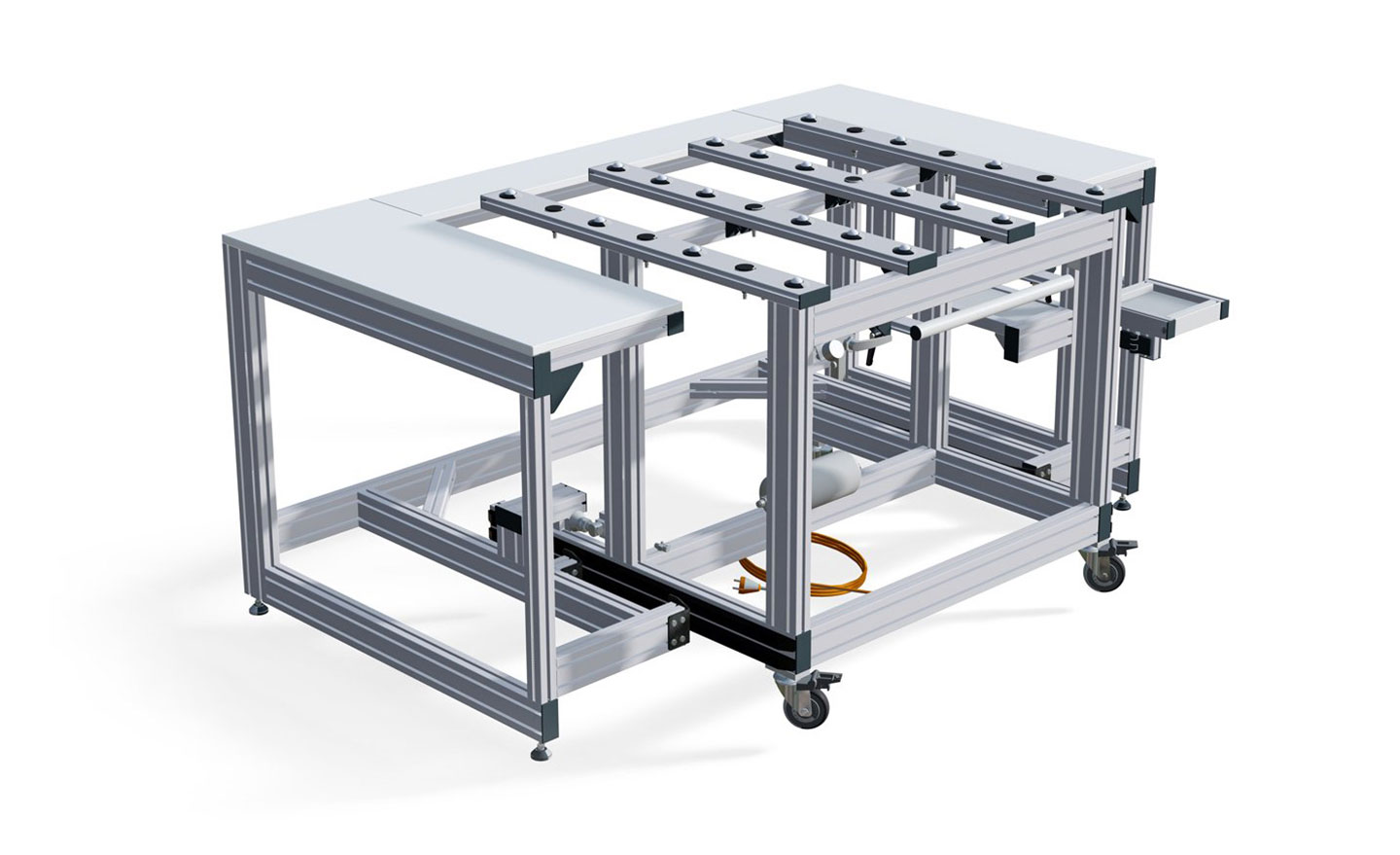

Module repair station, low-cost with previous transport trolley

- Products

- Solutions

- Service

- Company

The offline equipment serves as additional material to the product line of module production. Whether installed in your production line or as an extra, the offline equipment meets its helper function and is used by you as a repair station or to convey all kinds of different materials.

Our repair stations consist of a base frame, made up of many different aluminium profiles. Individual functions are achieved with expanded layouts. Different repair stations therefore result, for example, for modules, laminates or strings.

Module repair station, low-cost with previous transport trolley

Laminator repair station with a transport trolley

Suitable for the transport and storage of string boxes, cut films and rolled films. Based on various MiniTec profiles.

Film transport trolley

String box transport trolley

The operator equips the loading point with unprepared junction boxes and then starts the automatic machining by pressing a button. The preparation station attaches one or two strips of double-sided adhesive tape to the box first. If this operation is completed, a silicone bead must be made all round the box. The prepared box is then made available to the operator. The operator removes the box, equips the loading point with new boxes and starts a new process. To ensure reliable functioning of the preparation station, the levels of the individual consumables are monitored in a suitable way. The occupancy of the preparation station can be detected visually through transparent cladding.

Junction box adhesive application