- Products

- Solutions

- Service

- Company

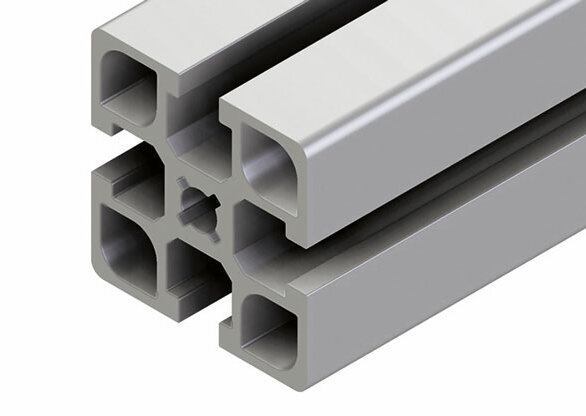

The MiniTec aluminium profile system, as a flexible modular system with perfectly coordinated components, enables fire services to fit out the interiors of their vehicles themselves. With our profile Series 30 and 45 we offer you a large selection of aluminium profiles in different sizes and geometries, which are compatible with each other.

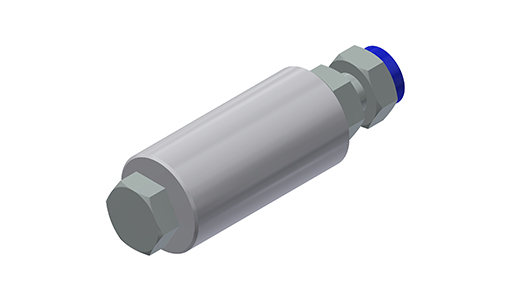

Individual designs are quickly planned, can be implemented in a very short time and despite this, thanks to the intelligent connection technology, can be changed again at any time.

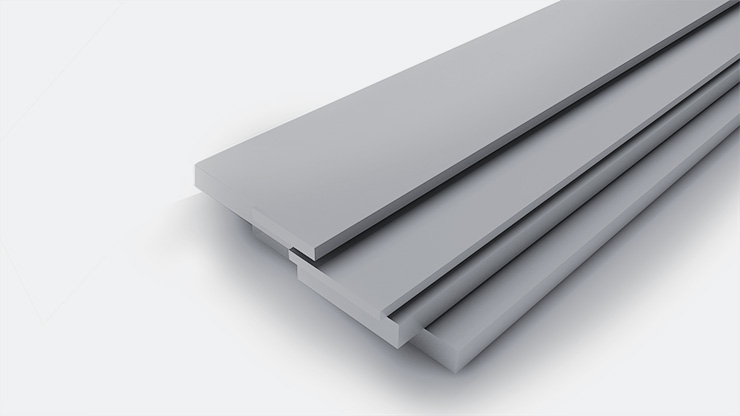

The lightweight aluminium profile series with 30 mm grid dimension is convincingly lightweight, is in the lower price segment and is ideally suitable for vehicle fit out with lower loads. All profiles in Series 30 can be combined with each other and all additional components in any way required, and this with the same tool and only one bolt and nut size.

The solid counterpart to the profile Series 30 is suitable, above all for vehicle and container fit out, when the loads are somewhat larger. Due to the uniform groove shape, the profiles in this series can also be expanded with each other and with all other additional components in any way required. Individual lengths and customised kits are available on request.

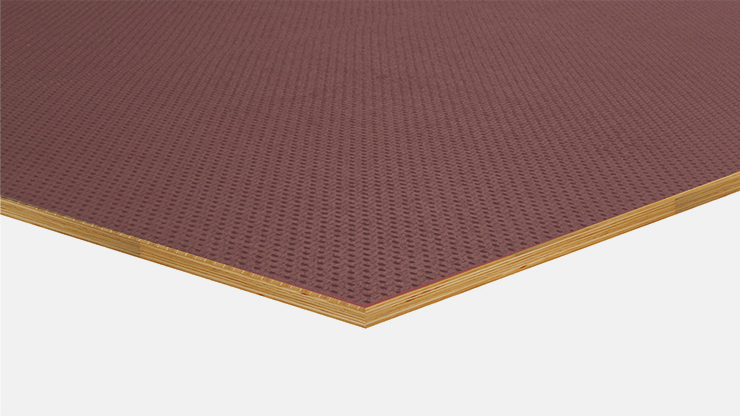

The optimum board material for vehicle fitout. Textured coated boards are veneered plywood boards made of birchwood, with a phenol resin coating and one-sided screen embossing. Due to this coating and BFU100 gluing, the boards are even waterproof. The screen embossing is for slip resistance. Surface colour: dark green

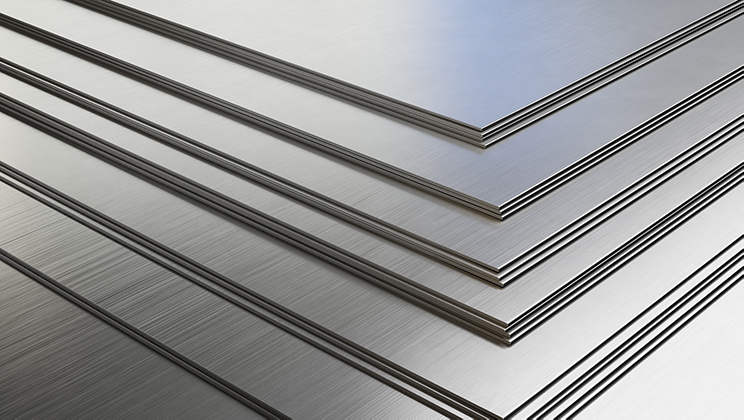

Aluminium sheets are lightweight, which is a major advantage in vehicle fit out. The sheets can be installed directly in a profile groove or screwed on from the outside, for example, to close off side panels in a profile rack. Different installation materials are available for this, for example, insert seal, square nuts and screws. Surfaces: anodised and film faced on one side or both sides (back or non-film faced side can have transport marks on it).

Duet aluminium chequer plates (2 bars next to each other) with raw, bright rolled finish. The diagonal ribbed structure (named chequers or diamonds) improves slip-resistance. The material is therefore in demand for use in vehicle fit out for floorings, shelving, ramps, etc.

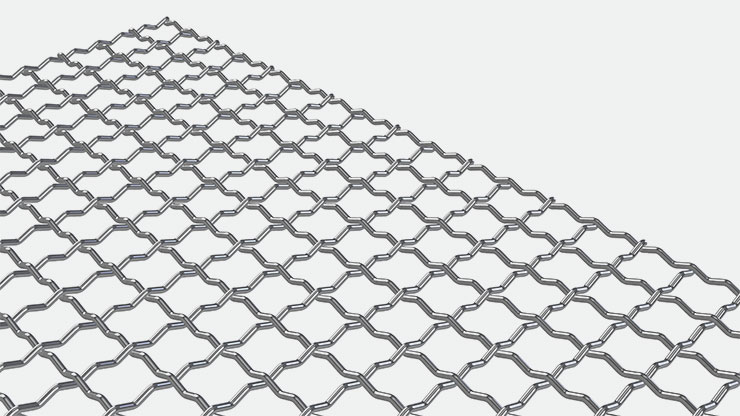

A corrugated mesh made of wire mesh is extremely robust and can be installed directly into a profile groove. Used in conjunction with the MiniTec profile system, for example, an individual partition can be installed in a crew car in next to no time. Diverse cages, safety fences, etc. can also be made.

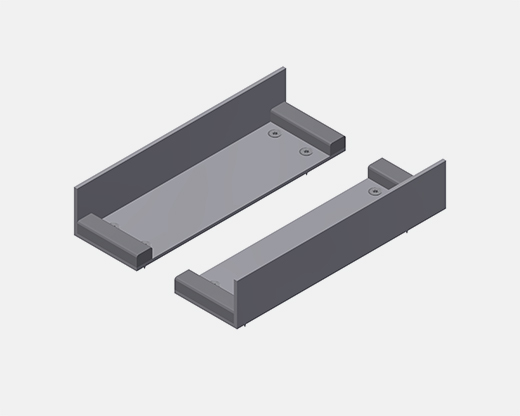

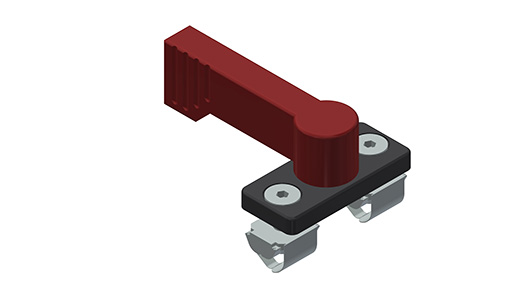

MiniTec mobile container racks are quickly and easily secured in the vehicle with the JF-System. Quick clamping levers can be positioned and fixed in any place of a JF sidewall rail with a flick of the wrist. It fixes mobile container racks on the side walls in equipment vehicles in seconds, and does so with a guaranteed loading capacity of 500 daN.

If you want to place three mobile container racks next to each other and this means there is no clear middle aisle, they can be secured with a KIM crossbar instead.

Made from the proven MiniTec profile system, with the clever connection technology without machining. This technology offers maximum flexibility.

MiniTec offers practical racks made from the aluminium profile system for storing LUKAS eDRAULIC spreaders and cutters.