- Products

- Solutions

- Service

- Company

The individual work steps are displayed to the worker at the work table via the controlled monitor with corresponding aids (texts, arrows, images, video clips etc.). If it is a touch screen, the worker can confirm completed work steps on the screen and forward to the next step. Confirmation can also be made via a keyboard or "buzzer".

Keyboards, as well as buzzers (operated by hand or foot), are used to confirm individual operations or make other acknowledgements to the system.

Pick To Light light bars are versatile. They can, for example, signal to the worker which compartment he has to reach into next. If they are equipped with an intervention monitoring function, the system detects whether the worker has reached into the relevant compartment and acknowledges this internally so that the next assembly step is indicated.

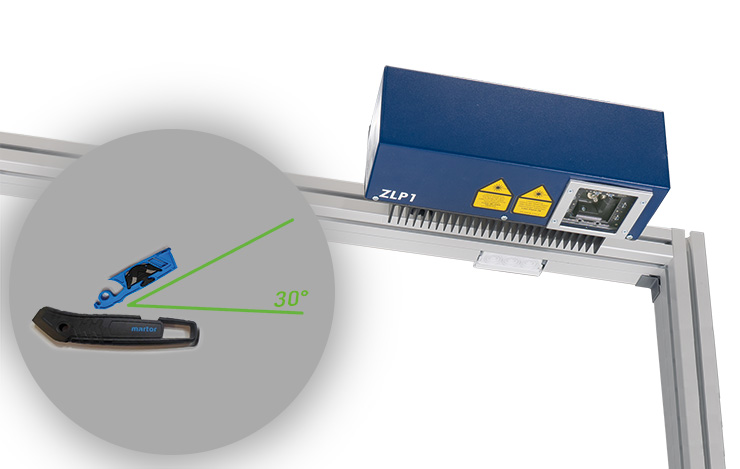

Another option for an optical positioning system is projection by laser beam. In this case, a special laser projector is mounted above the workstation. The assistance system automatically controls which object the laser should highlight during the assembly steps. Depending on the setup and orientation of the system, markings can be projected onto the work surface, components can be highlighted on it, or even objects (e.g. tools) and surfaces away from the work surface can be illuminated.

The laser projection can be not only a point. Rather, a variety of shapes are available for selection in the editor (e.g. rectangles, arrows, circles, ...). A freely rotatable arrow can be used to point out a detail with high precision. A polygon consisting of four freely adjustable corners can be configured in such a way that distortions are compensated. Thus, even obliquely illuminated surfaces are no problem for MiniTec SmartAssist.

The handheld scanner can be integrated into the work process in various ways, for example for starting processes or confirming work steps.

The "External tasks" module allows you to integrate external sub-processes into a MiniTec SmartAssist recipe. The result of this program execution can be evaluated by the assistance system and subsequent steps for success or failure can be configured. The module is therefore not function, but can be used extremely flexibly.

For example, within an assembly instruction at a the control of a printer can be integrated at a defined point within an assembly instruction, which creates an individual label including a barcode for the component component being assembled. Once the label is finished, a corresponding feedback can be sent to the system so that MiniTec SmartAssist can continue with the next step of the instructions.

Another application example is the triggering of test software, which carries out certain functional tests on the assembled component and returns the result (i.O./n.i.O.) to MiniTec SmartAssist. . Depending on this, the next assembly step is then carried out or it is branched off for troubleshooting.

The prerequisite for using the "External tasks" module is that the customer software to be controlled is available in exe format so that it can be started from MiniTec SmartAssist so that it can be started and processed.