- Products

- Solutions

- Service

- Company

The Baden-based company Gebrüder Wörner opted for the MiniTec aluminum profile system around 30 years ago. During this time, the special machine manufacturer and production service provider has created a wide range of different designs. The flexibility of the modular system continues to impress the engineers time and time again.

The modular profile system offers a high degree of flexibility for constructions of all kinds.

Partnership in action

Gebrüder Wörner opted for MiniTec as a supplier around 30 years ago.“Back then, we looked around for the right mechanical engineering company and partner and came across MiniTec.Both the offer with the modular system and the geographical proximity were decisive advantages,” says Daniel Bentz.But how a partnership really works can only be seen in practice.“We've had really good experiences here over the years.The collaboration works smoothly. We get fast and reliable information from both the field service and the technicians when we need it, the delivery times are short and the quality is right,” he adds.

The basis for almost all machines and systems built by the Baden-based company is the MiniTec profile system and the associated modular system. This has proven itself in many industrial sectors for decades and contains all the important parts and components: From ergonomic work tables to stable safety enclosures or machine frames to the construction of complex conveyor systems, there are no limits.

Everything fits together

The compatibility of the different profile sizes, which can be combined with each other, is a decisive factor for flexible use. As a rule, the user can choose between the lightweight version for particularly economical solutions, the closed version for sophisticated design or high hygiene requirements and the heavy-duty version for the toughest demands.This plays an important role for machine manufacturer Wörner, for example, as it also supplies food producers with the corresponding hygiene requirements in production.

Other important points include the possibility of an integrated compressed air supply or protection against electrostatic discharge thanks to ESD-capable components in the modular system.“We also build many devices, conveyor lines and workstations for our own CNC production and manufacturing services - always with MiniTec products.So it's important that we don't have to switch to other suppliers,” says Bentz.

Firmly and flexibly connected

The MiniTec profile connector plays an important role in the designs: this is simply screwed into the profile cross-section of one profile using a self-tapping screw and pushed into the groove of the other profile.An M8 grub screw then creates a friction-locked and ESD-compliant connection between the two profiles, eliminating the need for drilling. “This is really practical, because it means that a design can be changed or extended at a later date without leaving any traces, and we can also reuse the profiles,” emphasizes Bentz. Overall, all these features also reduce the amount of drawing, measuring and processing work to a minimum.

But it's not just the real, tangible products that make work easier: “We design all machines and systems using a professional 3D CAD system.It is therefore important that our supplier also provides the corresponding data,” emphasizes Bentz. MiniTec offers an electronic catalog for this purpose, which contains all components of the profile system as 2D and 3D data.These can be imported into all common CAD systems via standard interfaces.A parts list with the corresponding order information can also be created in this way.

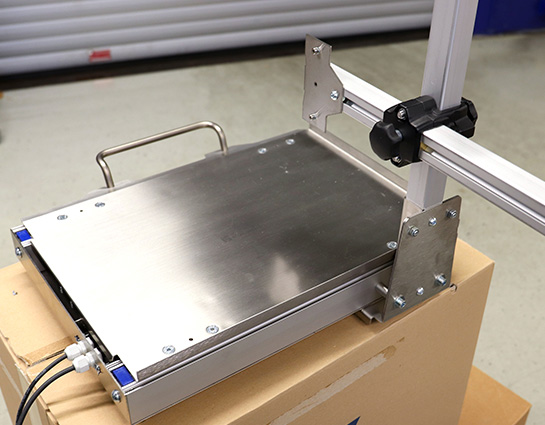

Also smaller standard devices, such as a marking system, are produced on the basis of the MiniTec modular system.

A well-coordinated team brings expertise in many areas.

Webshop with added value

“The new MiniTec webshop is also interesting for us.We signed up straight away and are convinced that it will make the ordering process even easier for us,” says Bentz.

Ordering via the store is very simple: the customer selects the desired products, defines the specifications and quantity and places them successively in the shopping cart. They then receive an automatic order confirmation.Once the order has been processed by MiniTec, it is followed by an order confirmation with all further details.

“All in all, a well-rounded solution,” says Daniel Bentz.The web store is a further service module that facilitates cooperation with MiniTec and saves the machine manufacturer Wörner time.

Gebrüder Wörner is a classic medium-sized company in the field of mechanical engineering, special machine construction and manufacturing services. Founded around 70 years ago, the company supplies individual parts, assemblies, tools, devices and special machines to well-known customers, including automotive suppliers and the packaging and mechanical engineering industries. The company employs around 20 people. The special machine construction division is now managed as a separate profit center. Daniel Bentz is responsible for this. The industrial master craftsman in electrical engineering is responsible for the areas of control technology, assembly and marking technology, but is also involved in product development.

The portfolio also includes laser marking booths that can be customized for the respective purposes. They are available in a basic or advanced version. They are equipped with a manual or electric lifting door and lifting table as standard, as well as a 3-axis hybrid laser with autofocus and a marking field of 125x125 mm.This is a good example of how advantageous MiniTec's modular system is for the mechanical engineering company when it comes to building very flexible frames and enclosures for systems.

Division Manager Daniel Bentz is responsible for special machine construction.