- Products

- Solutions

- Service

- Company

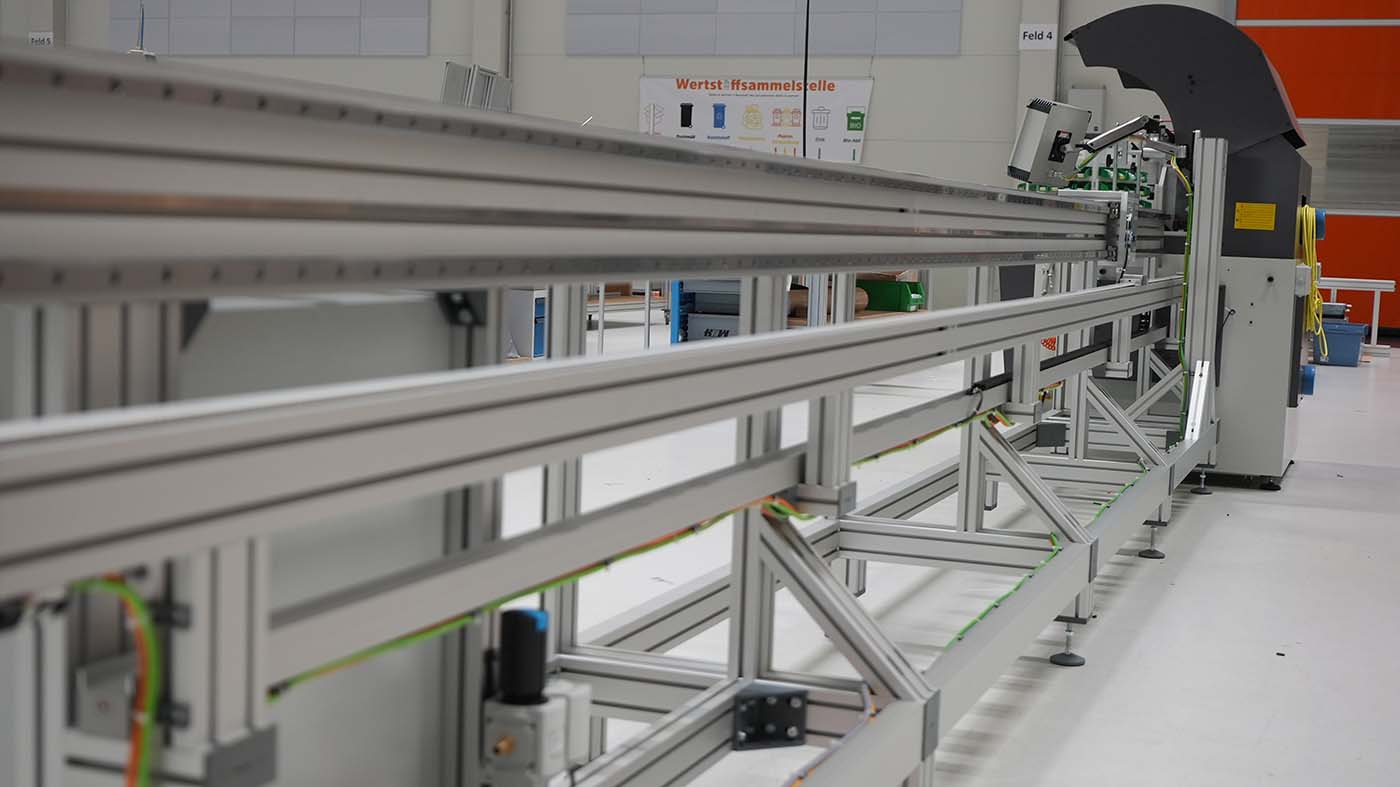

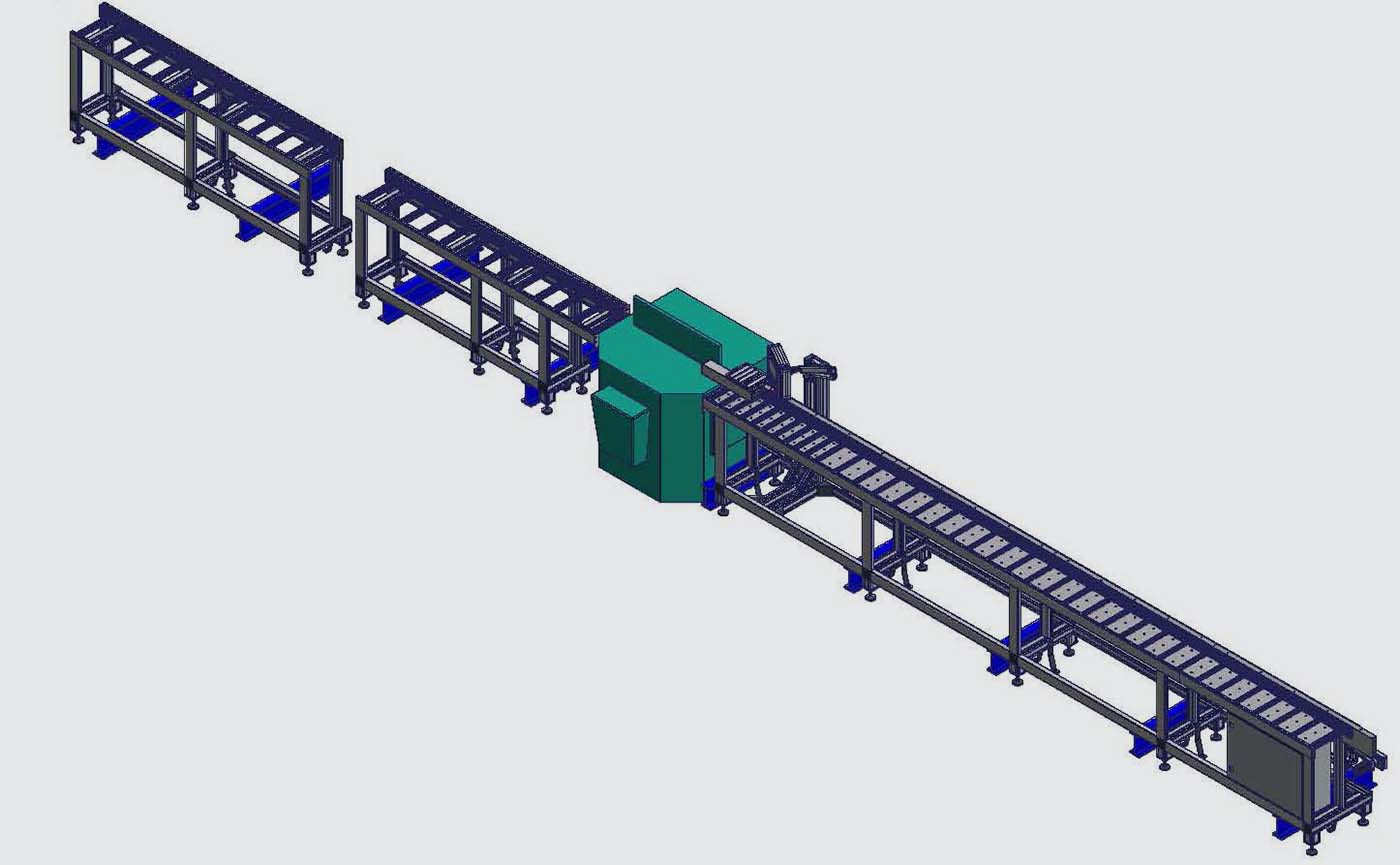

MiniTec can order aluminum profiles in any length between one centimeter and 6 meters. In order to be able to supply the East German customers quickly and flexibly from the Berlin location, the head office has now built a complete cutting facility for the branch on the Spree, consisting of a saw, frames for the infeed and outfeed, and a motor-driven length stop.

The system allows all aluminum profiles from the MiniTec range to be cut to size. For manual feeding, the profiles are placed on a roller conveyor. Brush rollers are used as rollers, which are particularly gentle on the material and prevent scratches or other damage to the aluminum.

The desired length is entered on a control panel. At the push of a button, the cross-cut fence then moves to the corresponding position. A linear rail guide with toothed belt drive serves as the travel path, making the design particularly robust and reliable. An absolute magnetic tape measuring system picks up the position directly on the carriage, thus ensuring high accuracy of the cut. Once the desired position has been reached, a pneumatic clamping system ensures that the carriage is firmly locked in place - this also serves to ensure precision.

The convenient control panel allows a large number of additional settings, for example for the traversing speed or the acceleration of the cross-cut fence. It also provides information on pending malfunction, warning and operating messages and can be used for diagnostic purposes.

MiniTec can of course also realize such and similar systems for customers. And not only when it comes to aluminum profiles, but also for other materials such as wood, plastic or steel. For example, a system is in operation at the Waldmohr site for cutting shafts from precision steel. Individual requirements can also be implemented without any problems, for example with regard to the width and length of the roller conveyors or if automatic feeding is required.

If you are interested, please contact us!

![[Translate to English:] Säge für MiniTec Profile](/fileadmin/user_upload/service/news/saege_berlin_01.jpg)