- Products

- Solutions

- Service

- Company

Flux-free soldering offers important advantages over other joining processes for certain areas of application. This is also the case at Zehnder GmbH in Lahr, where a corresponding MiniTec system is used in the production of tubular radiators.

Zehnder is an international full-service provider for indoor climate system solutions and a healthy indoor climate. The product portfolio is divided into the areas of designer radiators, comfortable room ventilation, heated and chilled ceilings and air purification systems. At its site in Lahr near the Black Forest, the innovative company manufactures, among other things, its ‘Zehnder Charleston’ tubular radiators for customers throughout Europe.

For many years, Zehnder has been using a fully automatic soldering system that works with a flux-free process to assemble the smaller radiators. It was originally purchased from the Berlin specialist W&P Wolf & Partner GmbH, which was taken over by MiniTec a few years ago.

Good reasons for soldering

Thierry Krebs, Head of Element Production, explains why this soldering technology and a corresponding system were chosen at the time: ‘In the past, the small radiators were manufactured using a special welding process. However, there were always major problems with dirt and necessary rework such as deburring etc., partly due to the limited space available. That's why we turned to Wolf und Partner to carry out tests with soldering technology as an alternative joining process.’ The aim was to produce clean radiators with less effort and less rework. After more than a year, the current system was created.

The ‘Zehnder Charleston’ tubular radiators are available to match any ambience.

High vertical range of manufacture

Most of the steps involved in manufacturing the radiators take place at the Zehnder site. Mainly the raw material, i.e. the tubes and coils (coiled metal strip), come from external suppliers. At Zehnder, the coils are first punched into half shells and then two halves are welded together to form a head piece.

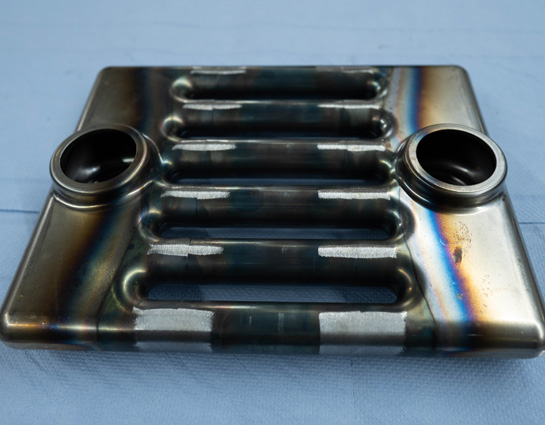

At the same time, the tubes are processed in various lengths. The brazing rings are then placed in the headers. The headers are then joined to the pipes and the soldering process is started. A head piece is soldered to each side of the pipe assembly, resulting in one element. The soldering process takes twelve seconds per element.

Accordingly, 1000 to 1500 elements are soldered per shift - depending on whether they have two, three or up to six pipes.

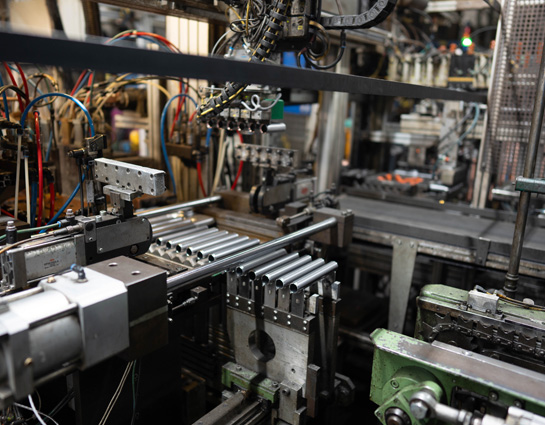

High degree of automation of the soldering system

The soldering system works fully automatically - there is only one employee to look after it and a grinder to check the quality. The individual parts come in, are positioned, soldered and conveyed out again. The tubes are provided as a bundle in the required quantity. The headers are automatically removed from the boxes and fitted with the brazing rings. After the subsequent brazing process, the parts come out of the brazing system and are first cooled down.

They are then ground automatically. Finally, an employee checks the 100 per cent tightness and visual quality of the finished parts. Once this has been confirmed, the soldered elements are first sent to a warehouse. From there, they are removed according to the customer's order and the radiators are manufactured using a quilting machine. After completion, the radiators are immersed in a water bath to check whether they are one hundred per cent leak-proof.

They are then hung up and sent to the shipping company via various other process steps, from priming and painting to packaging.

Many different radiators in the programme

According to Krebs, there is a simple reason why the soldered elements are initially stored temporarily and the actual radiators are only produced after the customer order has been placed: ‘We offer our customers great flexibility in the configuration of their radiators. In addition to the various standard types, special shapes and sizes are also possible. A curved radiator around a column, a radiator with five angles, a curved or s-shaped radiator, a radiator four or five metres high - whatever the customer wants, we can make it happen! There are also over 700 different colours to choose from.’

Soldering system with clear advantages

The soldering system is used especially for smaller radiators with a height of 260 to 400 mm. It ensures fewer process errors and greater processing accuracy. For Thierry Krebs, the advantages are obvious: ‘With the system, we can produce much more precise elements than before. All parts always look the same. There is no longer the problem of slag or weld spatter getting into the process where the tubes are assembled with the head piece. I always have the same result and also the best quality.’

Fully automatic: The soldering system in use.

No post-processing necessary: flux-free soldering delivers a clean result.

Inductive process

The MiniTec soldering system uses a flux-free process. In conventional systems, flux is used to ensure that the solder metal is evenly distributed. However, it is very harmful to the environment and to health.

It also represents a certain ‘time bomb’, as rust appears at the soldered joint after a certain time. For these reasons, more and more users want to do without flux, and for the same reasons MiniTec has been focussing exclusively on flux-free processes for years.

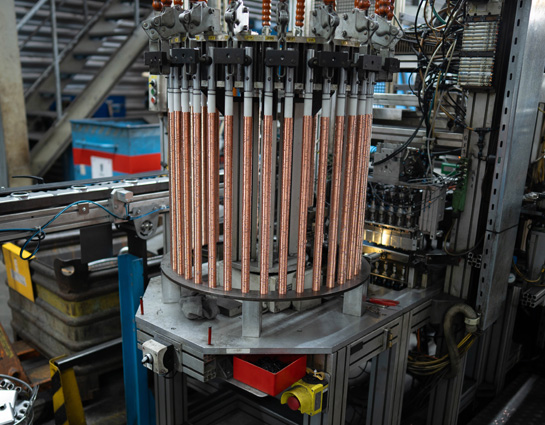

Krebs adds another advantage: ‘The process would be much more complicated with flux. It would not even be possible to produce the desired quantity in the required cycle time.’ In Zehnder's case, the workpiece is heated with the help of an inductor - and only at the point where the heat is needed.

The solder heats up, and as there is always shielding gas in the soldering chamber, it is distributed evenly over the soldering surface. Due to the capillary effect, it also reaches gaps and joints.

Inductive process

The MiniTec soldering system uses a flux-free process. In conventional systems, flux is used to ensure that the solder metal is evenly distributed. However, it is very harmful to the environment and to health.

It also represents a certain ‘time bomb’, as rust appears at the soldered joint after a certain time. For these reasons, more and more users want to do without flux, and for the same reasons MiniTec has been focussing exclusively on flux-free processes for years.

Krebs adds another advantage: ‘The process would be much more complicated with flux. It would not even be possible to produce the desired quantity in the required cycle time.’ In Zehnder's case, the workpiece is heated with the help of an inductor - and only at the point where the heat is needed.

The solder heats up, and as there is always shielding gas in the soldering chamber, it is distributed evenly over the soldering surface. Due to the capillary effect, it also reaches gaps and joints.

Do you need a suitable solution or an approach for your project? Then please contact us!