- Products

- Solutions

- Service

- Company

It's almost a classic - the desire to travel around the world in a motorhome as a pensioner. Sonja and Klaus are turning this dream into reality. The couple from the Karlsruhe area are currently converting a Steyr truck with MiniTec components into an expedition vehicle suitable for long-distance travel.

"It all started when we were thinking - what are we going to do when we stop working? That's when the idea matured that we could buy a motorhome and travel the world in it," says Sonja. She and her husband Klaus spent a long time looking around at trade fairs for a suitable vehicle. They were increasingly looking for a vehicle that would allow them to drive on more than just paved roads in order to be as flexible and independent as possible.

There were many interesting concepts on display, and a Unimog with a cabin on top was particularly appealing. The finished mobiles were tempting, but also had their disadvantages. They were not only very expensive, but also highly complex. This contradicted the basic idea of the two adventurers: "We wanted to be able to take care of the repairs ourselves if something breaks down. That's not a given if you have a high-tech vehicle. If you are somewhere where there is no mechanic and no workshop, you have to be able to do it yourself," says Klaus. In addition, the finished vehicles did not always meet the requirements in terms of layout and so on. That's why they decided to carry out the conversion themselves.

Mobile home from Sonja and Klaus - Steyr 12M18.

The globetrotter himself: Klaus assembling components.

Decommissioned military truck as the basis

A Steyr 12M18 was chosen as the starting vehicle. This is an old, decommissioned truck from the Austrian military (first registered in 1986). "The Steyr is not only stable, but also extremely suitable for off-road use. With a length of 7.50 m and a width of 2.55 m, it is not too big and has a relatively small turning circle. In addition, due to its age of over 30 years, there are virtually no electronics on board, which is a clear advantage in remote areas," emphasizes Klaus. The truck was completely refurbished and overhauled by the specialists at Excap from Lautertal-Gadernheim in the Odenwald. The result is impressive - the truck is back in top condition, both visually and technically, and ready for the next 30 years. The Krug Expedition company from Schladming in Austria then provided the body. It consists of a cabin including frame, windows and doors. It is 4.70 m long, 2.30 m wide and 2 m high inside.

Decision for MiniTec profile system

And suddenly MiniTec was involved, because after a visit to the Abenteuer & Allrad trade fair, they were quickly convinced of the advantages of the modular profile system for their own project. They decided to use MiniTec as the basis for the scaffolding for the interior fittings and all the furniture, says Sonja: "Clear lines and the ability to connect and disconnect things were simply important to us. The aluminum profiles are also relatively resistant to moisture. They are robust and you can build many shapes. You can get to everything on the inside because you can unscrew the installed panels again using the GD 30 multi-blocks from MiniTec. The MiniTec construction kit is the ideal solution for us." What's more, this method is much cheaper than having such furniture made by a carpenter.

iCAD Assembler of great benefit

Before deciding on MiniTec, Klaus, a CAD administrator by profession, had already created numerous designs for wooden camper furniture on the computer. He has now transferred these to the world of MiniTec aluminum profiles using the iCAD Assembler: "Because it's much easier to do this with it. You have all the components available, and the necessary connectors, cover caps etc. are also taken into account straight away. In addition, you are always informed about the prices." He then imported the designs from the iCAD assembler into his CAD system and continued working with them. Using the electronic design tools has clear advantages for the tinkerer because he can avoid errors in advance that would otherwise only be detected during installation.

On-site installation at MiniTec

After the preliminary work, it was time to get down to practical work in November. Klaus and Sonja were able to use MiniTec's assembly hall to assemble the components designed on the computer and then manufactured and installed in the vehicle. They were supported in word and deed by company employees.

Once everything is installed, the Steyr is sent to another company where the heating system is fitted. Then comes the electrics. "We have solar cells on the roof, a power connection for 220 and 110 volts as well as a connection via the truck's alternator so that the battery is charged when we are on the road. The electricity is the basis for almost all the appliances, only the heating is diesel-powered," says Sonja. Further elements will be installed and connected with external support by the end of the year: Stairs, lamps, heating, water tanks and gray water tank. After that, a lot of small jobs will be carried out in-house, including the installation of a bed. "When everything is finished, we'll have a complete condominium on 9 square meters," comments Klaus.

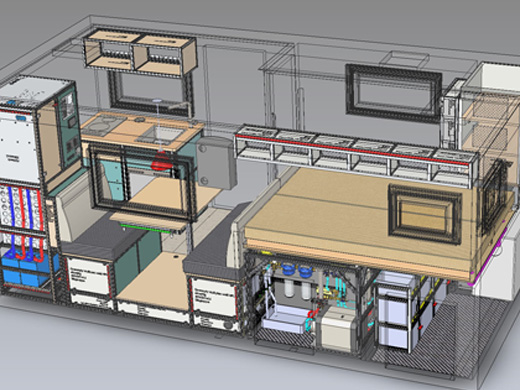

This is how it should be - CAD drawing of the extension.

The complex power supply.

After the basic work in the MiniTec halls, we then went to a motorhome service provider in November 2023, who installed the heating system. This has a total output of four kilowatts and consists of one component for the living area and a second for the cellar room at the rear. The same company then milled out the wooden panels for the table, the kitchen unit, the benches and other furniture elements.

Specialist companies for electrics and water supply

The next stop was a specialist company that took care of the electrics. Klaus explains: "It was about the complete power supply for the cabin. This began with the installation of two large batteries, each weighing 56 kg and with an output of several kW. Eight solar modules were mounted on the roof. Two frequency inverters and several converters were also added. These receive power from the alternator while driving to charge the batteries. If necessary, the electrical system in the cab also supplies the truck's starter battery with power if it is too weak." The work continued with details such as openings for the water pipes and for the air supply to the heaters. Some of the MiniTec racks also had to be anchored to the walls for the subsequent water removal - in sometimes cramped conditions. The vehicle was then taken back to a specialist to set up the water supply.

Live presentation at InHouse

The "home-related topics" included a kitchenette with electric stove and fridge as well as power sockets. The sanitary area with fans and cable ducts for the dry toilet was also on the agenda, as well as the exterior lighting, powerful USB sockets and three water pumps - one for fresh water, one for rinsing water and one for shower water. Much more work is still to come in the next few weeks. From installing the frames for the floors and the bench, fitting the shower tray, attaching wooden panels and installing the indirect lighting. The pair's aim is to have their long-distance truck as complete as possible by the InHouse on April 25 so that visitors can view it.

The kitchen unit is taking shape.

You can experience the upgraded world travel mobile "live" at our InHouse on 25.04.24.

Link to InHouse

Do you need a suitable solution or an approach for your project? Then please contact us!