- Products

- Solutions

- Service

- Company

Good training is essential for safe mastery of modern drive and automation technology. A customer from the automotive industry commissioned SEW-EURODRIVE to build a modular training model. Together with MiniTec, a solution was designed that can be flexibly adapted to new technologies and retains its CE marking even after a conversion.

SEW-EURODRIVE, headquartered in Bruchsal in northern Baden, is one of the global market leaders with products for drive automation. In over 90 years of company history, the company's innovations have always been pioneering in new technologies. With its modular drive system, SEW-EURODRIVE today enables over 45 million possible combinations for gearmotors alone. Another important factor here is that the Bruchsal-based company can offer a comprehensive support package. One of these support modules is support for the training and further education of specialists at the numerous customers.

Safety capitalized

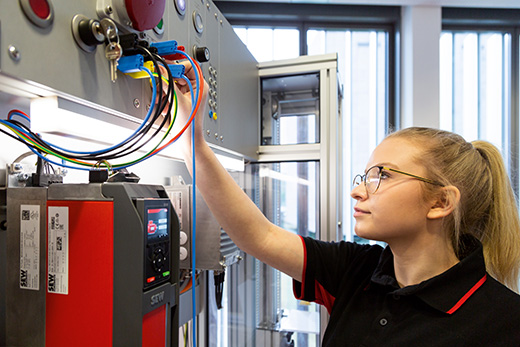

Practical practice on standard components is the most important guarantor of success for the learning outcome in vocational education and training. Correct electrical installation should also be taught in the process. Electrical voltages in the range of 230 V and 400 V respectively require a high degree of safety for the trainees and their instructors. Ultimately, work here is done on the "open heart". This requirement and the goal of reproducibility of the exercise series are met by using standardized connection technology via 4-mm safety test sockets.

Electrical safety is defined by VDE regulations and documented via a risk assessment in order to subsequently confirm functional safety to the user via CE certification. However, this declaration is only ever valid as long as a tested system is not modified. The ever shorter innovation cycles and increasing functionality in drive and automation technology also require constant adaptation to new technologies for such systems.

Flexible didactic model

A customer from the automotive industry commissioned SEW-EURODRIVE in 2021 to develop and produce a training model for professional development. This industry uses innovations and new drive technologies early in their production. In order to avoid costly adaptations of the models (installation effort and renewed complete CE certification), a new model philosophy was implemented here for the first time.

In close cooperation with the MiniTec design department, a transportable training rack was designed in which the basic electrical supply and the monitoring of the power and control voltage are integrated in the rack. The current drive components to be trained in the seminar can be individually assembled and installed. In addition, the installation of a linear axis system enables positioning exercises for finite and infinite motion sequences.

Declaration of conformity remains valid

The basis for this flexibility in exercises is the didactics portfolio from SEW-EURODRIVE. These training modules have CE certification and in combination with the new type of model rack, which is also CE certified, no new declaration of conformity has to be issued. The model concept is only subject to the annually recurring VDE test for portable electrical consumers. SEW-EURODRIVE and MiniTec are linked not only by the modular design principle, but also by many years of joint cooperation with a mutual customer-supplier relationship. Further information is available at www.sew-eurodrive.de/didaktik.

![[Translate to English:] Projektbetreuer Herr Wohlfahrt der Firma SEW](/fileadmin/user_upload/service/news/schulungsrack_2_520px.jpg)