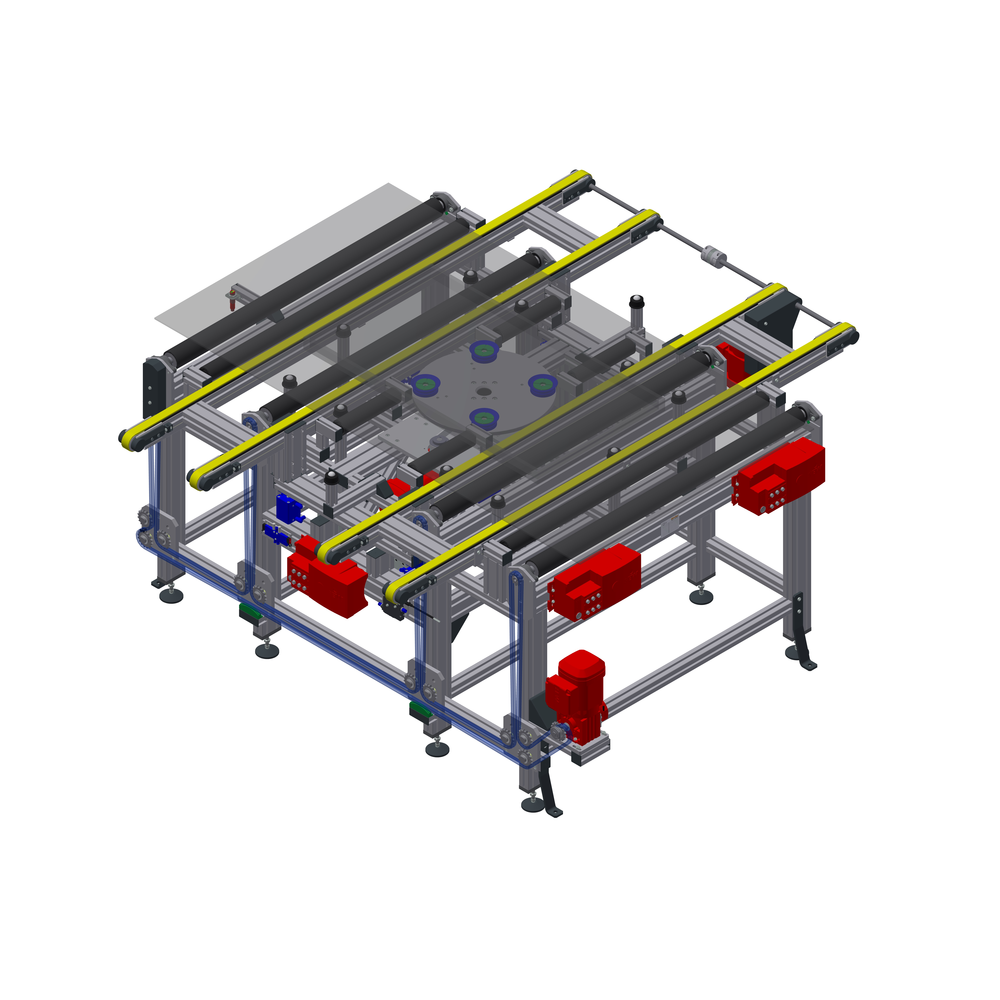

Corner belt conveyor including 90° turning station (bidirektional) 4-belts

- Version for backend

Version for frontend (additional ball roller lift-out)

- Built up from a corner transfer with integrated motor driven turning unit.

- Conveying direction 1 via driven roller conveyor, conveying direction 2 via timing belt conveyor.

- Turning unit equipped with 4 vacuum suction cups for fixing and torque transfer during the rotary movement.

- Timing belt conveyor for longitudinal transport with two drive belts, centre-to-centre distance approx. 2235mm.

- Inlet height approx. 1000 mm, outlet height approx. 1000mm (+/- 25mm adjustable using adjustable feet)

- 3x SEW motor with FU (frequency converter) and Profibus link, linear conveying speed approx. 240mm/s at 50Hz.

- 2 sensors for glass sheet detection: Creep speed/stop

- Rotary drive lifted out via a central pneumatic cylinder

Conveying direction change between SEL and LEL and vice versa. ->bidirectional

- A more or less extensive safety fence is required depending on the use.

- (LxWxH): 2200x2100x1100

- Power consumption: approx.0.6kW

- Weight = 400.000 kg/piece