- Products

- Solutions

- Service

- Company

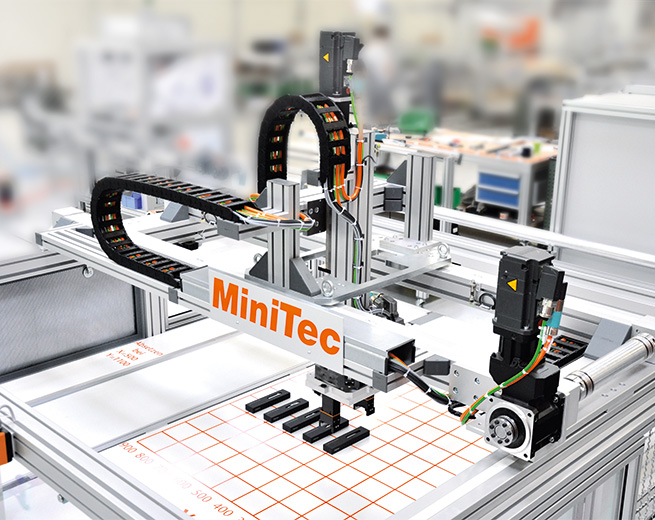

Our engineers produce ready-to-use solutions for every task in plant and special machinery construction for you, based on our profile system. That extends from the assembly workstation to conveyor and protection systems through to highly automated complete solutions. As a full-service provider, we are your reliable partner, from the process analysis to commissioning on site and training and support.

In line with our motto “The Art of Simplicity”, we design automation solutions with which we permanently increase and optimise the productivity and efficiency of our customers.

Particular requirements need special concepts. This is why our engineers produce specific solutions for an increasing number of industrial sectors.

Bringing workpieces to the right place, in the right position and at the right time; we solve this task with our conveyor technology.

Highly flexible workplaces can be implemented due to the modular structure and computability of our system components.

In automated, industrial production, increasingly complex products makes quality testing indispensable.

MiniTec develops custom-built workstations for flux-free gas-shielded brazing.

Individual protection devices are a frequent application of the MiniTec profile system. They are adapted to the customer’s exact wishes and meet the high requirements of all safety standards and machine guidelines.

Thanks to many years of know-how and our own production, all MiniTec linear systems are based on high-quality linear technology, including high-precision linear guides and precision steel shafts.

Intelligent warehousing is the key to optimized inventories, speedy production and satisfied customers. Find out which components and solutions we can offer you in this area by looking at MiniTec's warehouse logistics system.

The system guides the worker step by step through the work process by displaying the respective required activities on the screen with the help of texts, graphics or photos.